Industrial Tri-Proof Tubular Lighting Systems

Engineered for harsh environments and long-term industrial operation

LED Tri-Proof Tubular Lights Manufacturer

Designed to withstand water, moisture, dust, impact and long operating cycles

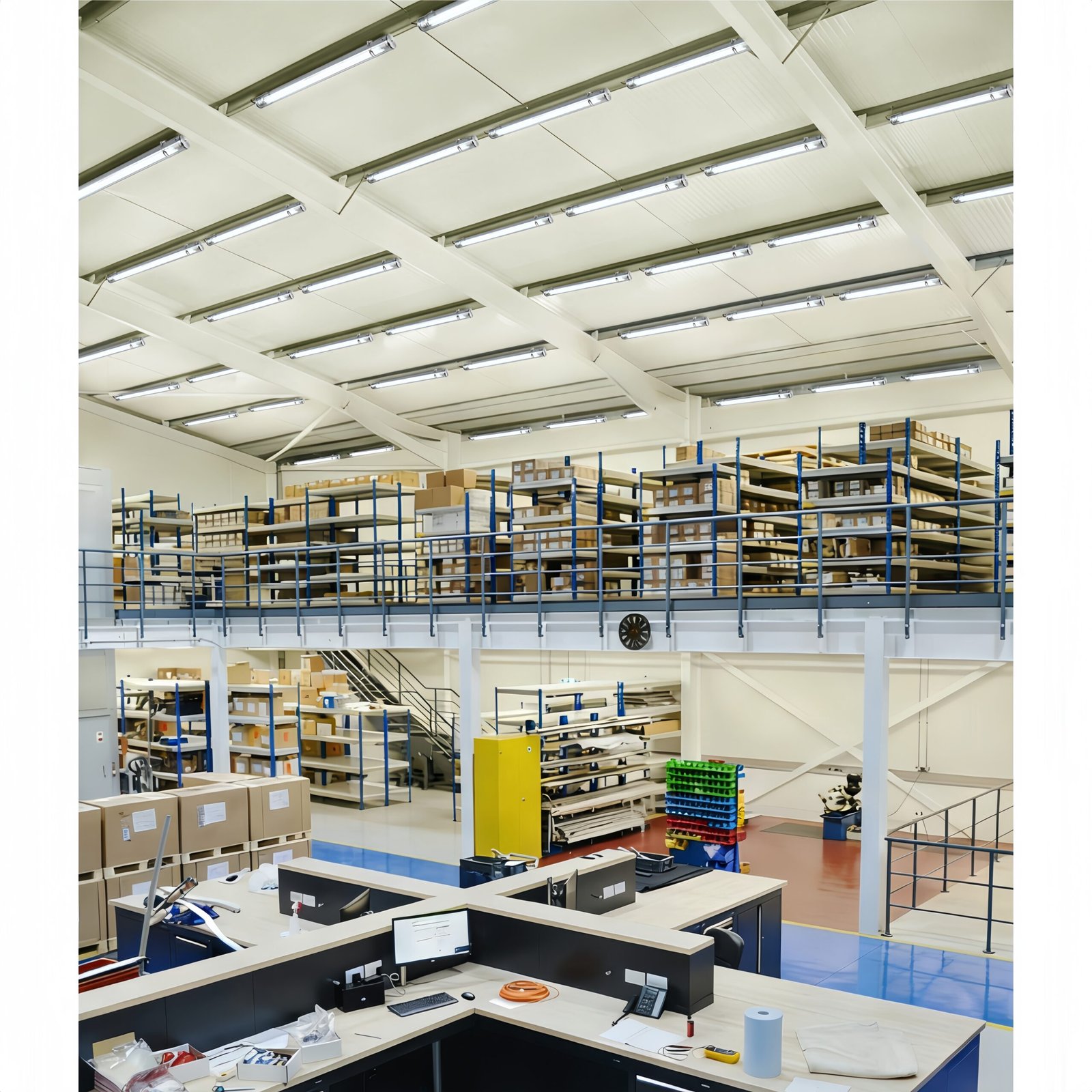

Our industrial tri-proof tubular lighting systems are engineered and manufactured to meet the demanding conditions of industrial and infrastructure environments, including industrial facilities, wash-down zones, transportation infrastructure, parking structures and hygiene-critical areas.

With ingress protection ratings up to IP67 / IP69K and impact resistance up to IK10, our luminaires are designed to withstand water, dust, high-pressure washdown and mechanical stress in continuous operation.

Robust housing construction, reliable sealing structures and controlled assembly processes ensure consistent performance, safety and durability over extended service life.

Industrial Tri-Proof Tubular Light Series Overview

⌀45mm

Designed for compact installations and high-impact risk areas, where space is limited but mechanical protection and washdown resistance are essential.

⌀70mm

A balanced solution offering uniform illumination, strong impact resistance and high-pressure washdown performance for general industrial and infrastructure applications.

⌀100mm

Designed for high-output lighting and heavy-duty environments, providing enhanced visual presence and robustness for large spaces and demanding washdown zones.

⌀75mm

Borosilicate glass housing for food, chemical, and marine applications requiring maximum chemical, hygiene resistance, and long-term material stability.

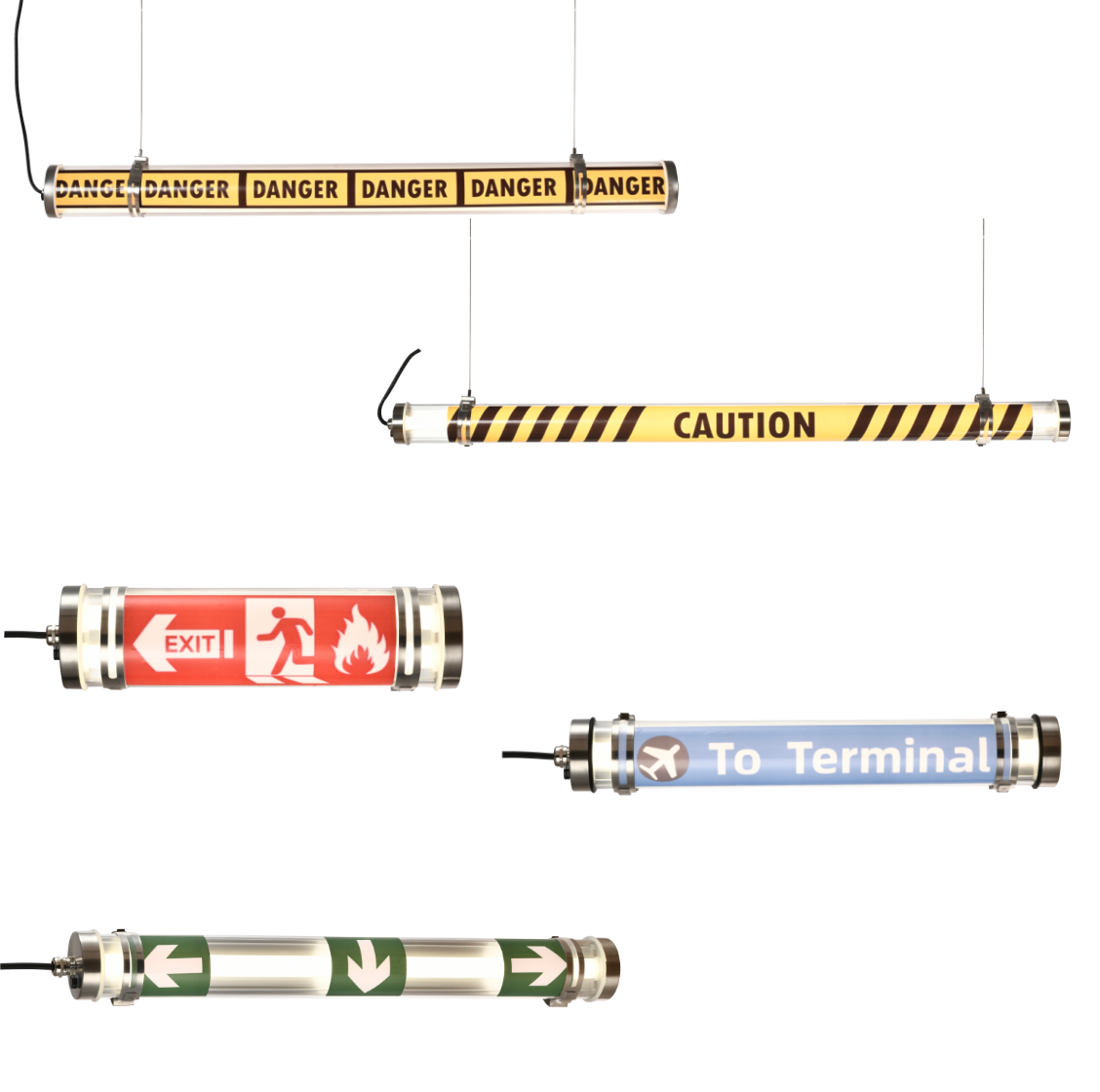

⌀45/70/100/75mm

Tri-Proof Tubular LED luminaires with customizable UV-printed or stickers for safety messaging, wayfinding, branding, and visual communication

Key Features

Waterproof & Moisture-Proof

IP67 / IP69K protection enables use in rain-exposed areas, wash-down zones, steam cleaning environments and humid industrial facilities.

Dust & Particle Tight

Triple sealed housings prevent dust ingress, making the luminaires suitable for dusty factories, woodworking shops, stone processing facilities and logistics centers.

Corrosion & Chemical Resistance

UV-stable PC / PMMA / borosilicate glass housings, combined with 304L / 316L stainless steel, provide resistance to ammonia, solvents, salts and chemical fumes.

Impact & Vibration Resistant

Designed to meet IK10 (IEC 60068) standards, withstanding mechanical shocks, heavy handling and vibration from machinery or transportation.

High-Efficiency LED & Driver

High-efficiency LED systems deliver 120–150 lm/W system efficacy, supporting bright, even illumination with optional high-CRI configurations.

Stable, flicker-free drivers ensure visual comfort and reliability in safety-critical environments such as parking garages, platforms and industrial circulation zones where visibility is essential.

Long Lifetime & Low Maintenance

The combination of high-quality LEDs, sealed housings and robust construction enables 50,000–100,000 hour lifespans, significantly reducing relamping frequency and maintenance downtime.

This makes the system ideal for installations where access is limited or operational continuity is critical.

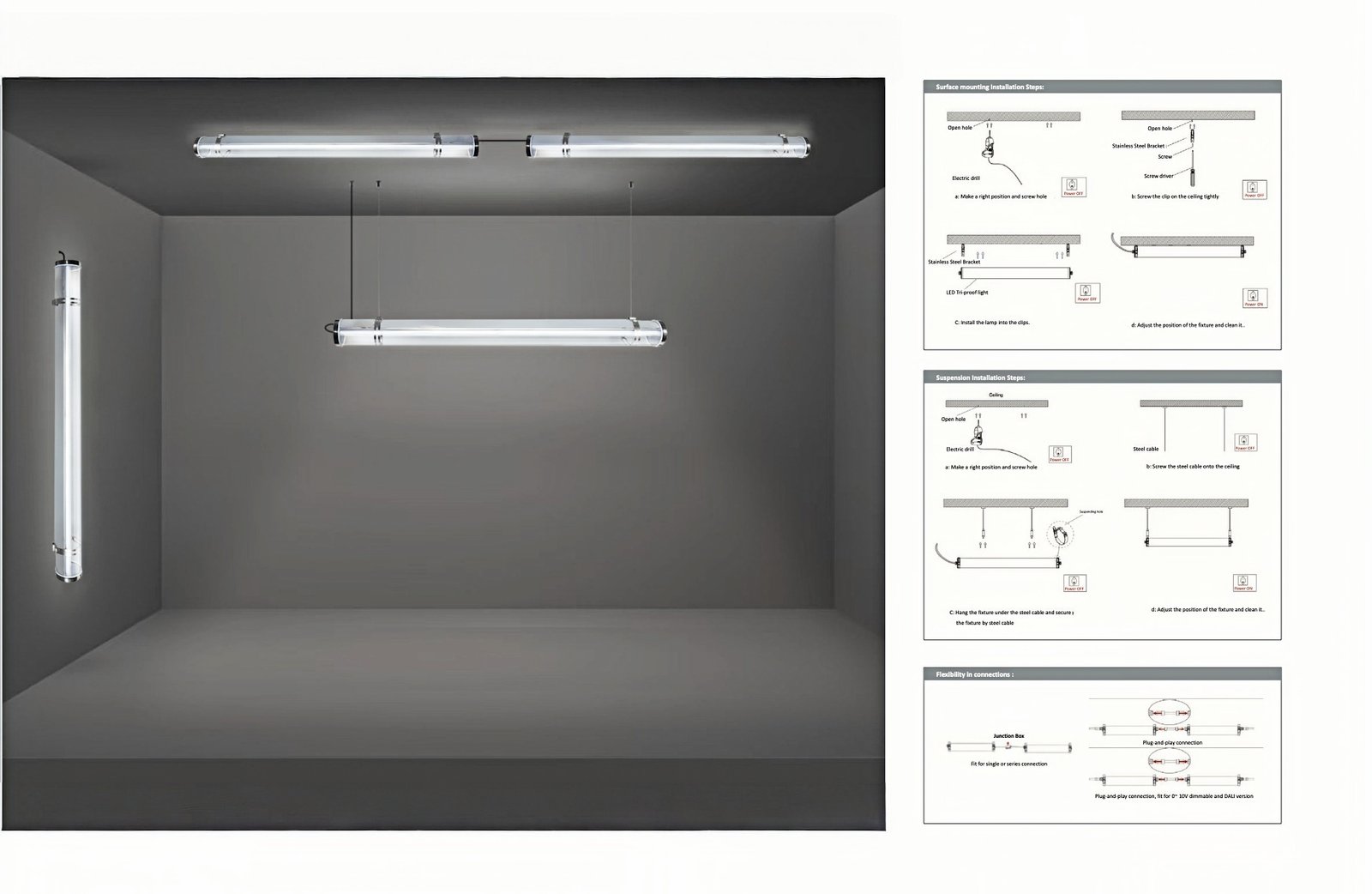

Flexible Installation

Tri-proof tubular luminaires support multiple mounting methods, including: surface-mounted and suspended.

Through-wiring (3-core / 5-core) and continuous-run linking options enable clean linear installations with fewer junction boxes, suitable for both new builds and retrofit projects.

Customizable & Modular

Different diameters (45/70/75/100mm), tube types (transparent, opal, PC, PMMA, GLASS), CCT, CRI, mounting method, control, emergency & sensor versions, labeling or signage printing.

Housing Material Guide

Selecting the appropriate housing material is critical to ensuring long-term performance in different industrial environments.

Bayer PC (Polycarbonate) – IK10

Manufactured from German Bayer (Covestro) PC resin, offering high impact strength, flame-retardant properties and strong resistance to vibration and wash-downs.

Passes the 960°C Glow-Wire Test, ensuring electrical safety under fault conditions.

Ideal for high-impact areas, logistics centers and vibration-intensive facilities.

Optical PMMA (Acrylic) – IK07–IK08

High-transmission PMMA (92–93%) for applications prioritizing visual uniformity and clarity.

Provides excellent long-term anti-yellowing performance, suitable for environments with lower mechanical impact.

Borosilicate Glass – IK08

High-hardness, scratch-resistant glass for chemical, food, pharmaceutical and marine environments.

Offers zero yellowing, maximum chemical resistance and superior UV stability.

Installation & Maintenance Benefits

Fast suspension or surface mounting minimizes installation time and labor cost in industrial facilities

Through-wiring and continuous-run linking enable long linear installations with fewer junction points, reducing wiring complexity

Corrosion-resistant materials and fully sealed housings support wash-down zones, chemical exposure and dust-heavy industrial environments

Long service life, high system efficiency and a 5-year warranty reduce energy consumption, maintenance frequency and total lifecycle cost

Customization & OEM / Project Support

Customization Options

Custom diameters, lengths, wattages, CCT, CRI and optics

Optional sensors, emergency battery backup

DALI / 0–10V / Triac dimming control

Custom branding, labeling and safety signage printing

Project & OEM Services

Flexible MOQ for pilot projects, scalable for large rollouts

Full documentation: IES / LDT files, BIM / CAD models, wiring diagrams, certification reports

Export-ready packaging and global logistics support for distributors and contractors

Design, Specification & Procurement Support

IES/LDT photometric files

CAD files

Compliance documentation

Project SKU standardization

Spare parts programs

Distributor support pricing

Compliance & Standards

Our industrial tri-proof tubular lighting systems are developed in accordance with international safety and performance standards to support inspection and project compliance.

IEC 60598 (Luminaires)

IEC 60068 (Impact & vibration testing)

IP67 / IP69K ingress protection

IK10 impact resistance

- 960°C Glow Wire Test (IEC 60695)

LM80 / TM21 LED lifetime evaluation

CE / RoHS compliance

- Project-specific datasheets

Certifications & Test Reports & Patents

Certified to global standards, with full test reports and patented technologies.

Full test reports and compliance documentation are available to support project approval and tender requirements.

Industrial Tri-Proof Tubular Lighting – FAQ

Tri-proof lighting refers to luminaires designed to resist water, dust and corrosion, making them suitable for harsh industrial environments.

In practical terms, industrial tri-proof tubular lights are built with sealed housings, durable materials and impact-resistant structures to ensure reliable operation in wet, dusty, vibration-prone or chemically exposed areas.

Industrial tri-proof tubular lighting systems are available with IP65, IP67 and IP69K ingress protection, depending on application requirements.

IP65 – Protection against dust and water jets

IP67 – Protection against temporary immersion

IP69K – Protection against high-pressure, high-temperature wash-down

Higher IP ratings are recommended for wash-down zones, food processing facilities and outdoor industrial environments.

Depending on housing material and construction, industrial tri-proof tubular luminaires can achieve IK08 to IK10 impact resistance in accordance with IEC 60068 standards.

IK08 – Suitable for general industrial areas

IK10 – Designed for high-impact and vandal-prone environments

IK10 versions are commonly used in parking garages, logistics centers and heavy-duty industrial facilities.

Housing material selection depends on mechanical impact risk, chemical exposure and hygiene requirements:

Polycarbonate (PC) – High impact resistance (up to IK10), ideal for heavy-impact and vibration-intensive areas

PMMA (Acrylic) – High optical clarity and uniformity, suitable for environments with lower mechanical impact

Borosilicate Glass – Excellent chemical resistance and zero yellowing, ideal for food, pharmaceutical, chemical and marine environments

Choosing the correct material is critical for long-term performance and safety.

Yes. With IP67 / IP69K protection, sealed housings and corrosion-resistant materials, industrial tri-proof tubular luminaires are well suited for wash-down zones, food & beverage processing plants and hygiene-critical environments.

Optional borosilicate glass housings further support chemical resistance and hygienic cleaning requirements.

Yes. Continuous-run linking with through-wiring is available, enabling long linear installations for corridors, tunnels, parking garages and production lines.

This reduces installation time, simplifies wiring layouts and improves visual uniformity.

Industrial tri-proof tubular lighting systems can be configured with:

On/off or dimming drivers

DALI / 0–10V / Triac dimming

Motion or microwave sensors

Emergency battery backup

Options depend on project requirements and regulatory standards.

Yes. OEM and project-based customization is supported, including:

Custom diameters, lengths and wattages

CCT, CRI and optical configurations

Housing materials and finishes

Custom labeling, branding and safety signage printing

Flexible MOQs are available for pilot projects and scalable production.

Typical applications include:

Industrial production facilities and workshops

Warehouses and logistics centers

Parking garages and underground corridors

Tunnels and transportation infrastructure

Food processing, cold storage and wash-down areas

These environments require durable, maintenance-free and high-performance lighting solutions.